W.I.D.I.R.L #2

I had a pretty good idea what I wanted to do. The first phase would be to modify the frame and suspension to suit the task. From my day job I know how to reverse engineer (copy) the important dimensions of components or complete assemblies. I use my milling machine with a digital readout or sometimes string and laser beams. I made some interesting discoveries and realized parts from other motorcycles could be found that were more suitable. For example, the best handling trials bikes all had the same combination of fork total offset and leg rake. I only had to alter the position of the Suzuki head tube to make it work.

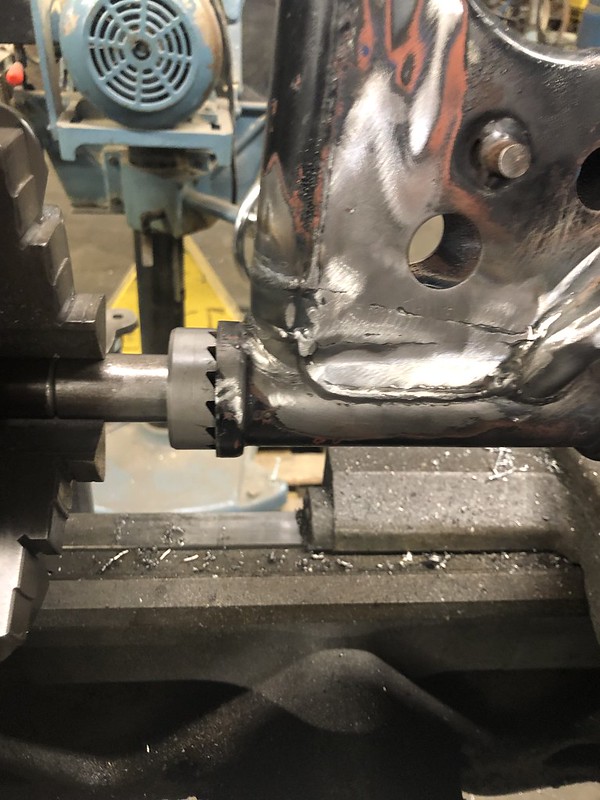

I found that I could simply cut the front of the frame off and weld it back on at a different angle. The crowns that had the best angle are for a Honda TLR (a popular vintage trials platform) and custom CNC machined versions are available through W.C. Machine right here in Vermont. The Honda head tube is longer so I machined the stock bearing cups away and welded in ones I made to fit tapered bearings.

(this is a photo from the future)

(this is a photo from the future)

Because trials bikes are made for riding over weird obstacles they have increased ground clearance and sturdy “skid plates” under the engine. Amateurs like myself use them more than high-level riders so I made mine from 6061 1/4″ thick and formed it with our 55 ton press. I removed the bottom tubes on the frame to fit it up tight to the bottom of the motor.

The frame is upside down and you can see the drain plug hole and mounting points. I have reduced the size since this photo was taken.

The frame is upside down and you can see the drain plug hole and mounting points. I have reduced the size since this photo was taken.

This next series of photos represents a big move forward. To achieve the ground clearance and correct ride height I need to angle the swing arm a bit. To do this I could use longer shocks (very long) or lower the upper shock mounts. ( I should draw a picture)

(Going back a moment in time, this is a quick cut/paste type of project) so I just cut tubes and moved them where they should be and spliced everything together to make it work. The cool thing is the frame still looks “stock ” and I feel okay about cutting it apart to make changes

I also “bobbed” the seat support tube at the fender loop and added pin tubes.

I relocated my footpegs (foot rests) so they are at the front of the rear tire and level with the bottom of the bike and made a seat support bridge.

I relocated my footpegs (foot rests) so they are at the front of the rear tire and level with the bottom of the bike and made a seat support bridge.

The most unimaginable thing I do is provide the fertile grounds that gives life to amazing high level projects. The time I spend burning paint and jamming Sawzall blades through “water pipe” frame tube has given me a lot of knowledge, inspiration and confidence.

It’s sort of weird but I need some distraction to prepare me for things that matter. Things I do in real life.

Comments

W.I.D.I.R.L #2 — No Comments

HTML tags allowed in your comment: <a href="" title=""> <abbr title=""> <acronym title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s> <strike> <strong>