Yeti sherpa resoration.

Yeti was a fun place to work. Skip, who works with me at FTW also worked at Yeti. Skip worked in the paint department so he knows some things I don’t.

I have seen a few rusty Yeti frames. Usually older ones. John and Linda lived at the beach and we rode the Malibu hills from time to time. When Chris and I started helping John he gave me a red FRO frame that was pretty rusty. We never imagined people would be collecting them. John came from a racing background and most racing machines are discarded, quite unceremoniously in favor of a new machine.

We love our old bikes don’t we? I sure love mine and this proud owner loves his.

I was a little intimidated by the project actually. I have a really amazing tube bending set-up but the yeti stays were something I never personally did. I drew pictures of them and mocked them into frames but that’s it. All the Bending at Yeti was done by an aircraft contractor in Burbank.

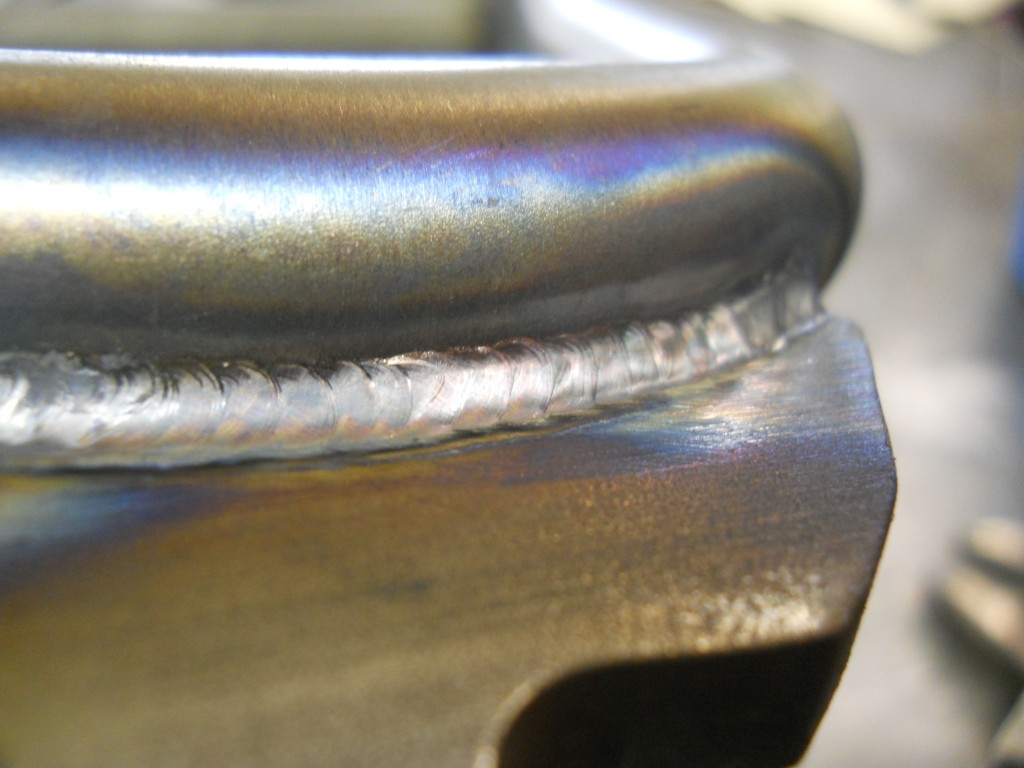

Bending 4130 in a small radius is very difficult. The mandrel penetration is critical and the tube must be coated with a high-pressure lubricant. I didn’t have the right mandrel so the whole process began with making a proper mandrel and heat treating it for durability.

It takes several bends to have one work properly. The tubes will either snap (mandrel too deep) or buckle (too shallow) but by the sixth or so try, it works. I pull a few more for good luck.

The actual stay tube is nearly 1M (3′) long before bending. There is limited access around the bending dies so each bends location must be planned. On the original tail, the beginning and ending of each bend must be marked and the amount of tube for each bend accurately calculated. On the left side, the bends at the lower tire and pedal are done first, then the tube flipped, end to end and the upper tire bend done. On the right side, the opposite sequence is used. Each bend has a correct measurement but before each bend, the tube must be rotated and over-bend estimated.

I have to turn the music off, stand on one foot and hop around with my eyes closed to visualize the parts in a 3-D state being formed. I am pretty good at “mental 3D modeling” but it’s still an effort.

I ended up only getting one set of these tubes done before simply running out of everything. Thankfully, they are perfect.

I re-used the original brake bosses and added vent holes.

Today (tomorrow), I am making some old forks.

I even used old-school parts to test fit everything!

Comments

Yeti sherpa resoration. — No Comments

HTML tags allowed in your comment: <a href="" title=""> <abbr title=""> <acronym title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s> <strike> <strong>